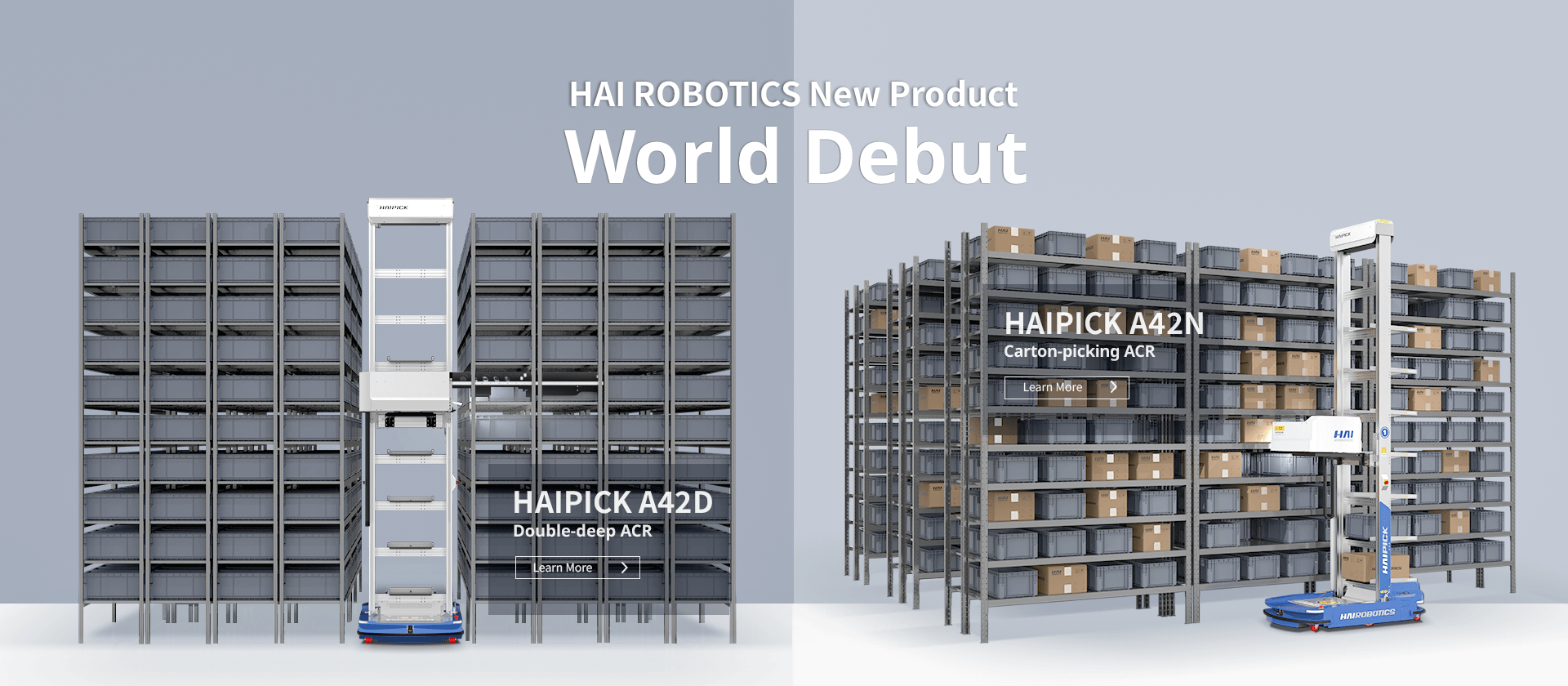

Hai Robotics Launches World’s First Carton-picking & Double-deep Autonomous Case-handling Mobile Robots

Hai Robotics held an online product launch conference to showcase the new HAIPICK robots: the world's first carton-picking ACR HAIPICK A42N and double-deep ACR HAIPICK A42D.

As a pioneer in autonomous case-handling robotic systems, Hai Robotics automates warehousing with its HaiPick systems.

Warehouse Robots Launch Conference

On June 15th, 2020, Hai Robotics held an online product launch conference to showcase the new HaiPick robots: the world's first carton-picking ACR HaiPick A42N and double-deep ACR HaiPick A42D.

The rising rental cost of warehouses has become a major issue for many companies. Warehouse managers are constantly looking for the most cost and storage-efficient solution.

HaiPick A42D Double-deep ACR

HaiPick A42D is the world's first double-deep ACR that optimizes space usage and increases storage density in warehouses.

* Reduces the number of aisles by up to 50%

* Increases the storage density by 130% compared with traditional manual warehouses

* Customizable telescopic fork for easy access to two rows using double-deep shelving

* The intelligent optimization algorithm can be tailored to match diverse business models and optimize the accessibility of stock

Hai Robotics' strong R&D capabilities allowed the company to develop HaiPick A42D in 1.5 years successfully passing a series of tests.

In March 2020, the first HaiPick A42D-based system started operations in a 3PL company project and gained positive feedback from the client.

HaiPick A42N Carton-picking ACR

HaiPick A42N is the world's first carton-picking ACR. It enables warehouse operations to use cartons as handling units rather than only totes.

* 3D visual recognition technology identifies goods without codes in cases

* Supports multi-size carton/tote picking, applicable to multiple business needs

* The software platform is tailored to support case-picking and piece-picking modes to cater to different businesses’ needs

* Cartons and totes can be reused to lower costs

* Faster inventory count through shelf scanning using 3D visual technology

HaiPick A42N will enable even more warehouse operations to choose autonomous case-handling robots in the future. The above features have already been proven and put into commercial operation since May 2020.

Advantages of HaiPick System

HaiPick systems provide flexible, high-efficient warehouse operations to address warehouse issues and cater to dynamic business changes:

* Self-optimizing

HaiPick transforms warehouse operations with automated transportation, retrieval, storage, and sortation. The intelligent optimization algorithm is tailored to fit the client's industry and self-optimizes accordingly over time.

* High efficiency

Compared with traditional manual warehouses, HaiPick can increase storage density by 80%-130% and improve operation efficiency by 3-4 times.

* Flexibility

HaiPick supports the interaction with various equipment for integration or customized solutions. It is convenient for clients to expand, relocate or rearrange in response to business changes.

* Short-term ROI

Industry-leading payback periods for warehouse operations that qualify.

* Fast implementation

Warehouses can be automated within one week and go live within one month.

* Customized solutions

Hai Robotics and our local partners provide a variety of services to integrate HaiPick automation with other technologies and software platforms.

* Global patent layout.

With our global strategy of patents, Hai Robotics protects the benefits of inventors and clients.

Dedicated to the R&D in autonomous case-handling robotic (ACR) system, Hai Robotics successfully launched the first ACR system already in 2015. Regarded as a pioneer and inventor, Hai Robotics has been building on this position ever since. HaiPick models A42N and A42D are the latest results of this dedication to enabling next-generation warehousing solutions.