HaiPick System Boosts Micro-fulfillment Centers in Europe for Faster Online Orders

The fastest and most efficient way to fulfill online orders has become a top supply chain priority for automated fulfillment centers.

The search for the fastest and most efficient way to fulfill online orders has become a top supply chain priority for grocery retailers and e-commerce enterprises. Micro-fulfillment centers in Europe are leveraging robotics automation to shorten the distance for faster deliveries.

The need for speed

Less than a decade ago, distribution centers were the primary source of products moving to retail stores and end consumers. However, since the COVID19 pandemic first hit, the increasing customer expectations of fast delivery have made this model unsustainable. With increasing consumer demands for fast delivery, what used to be three days in one day, what used to be one day is the same day. As a result, the search for the fastest and most efficient way to fulfill online orders has become a top supply chain priority for grocery retailers and e-commerce enterprises.

E-commerce sales worldwide are expected to reach $6 trillion by 2024, from $5 trillion in 2022 (1), as people purchase more online, customer requirements and expectations drive the need for faster fulfillment. Combined with escalating labor challenges, the shortage of space, and the need to digitize fulfillment and supply chain logistics, e-commerce pressures have created the perfect breeding ground for micro-fulfillment strategies.

What is MFC?

Micro-fulfillment is an order fulfillment strategy that places small-scale, automated warehouse facilities in densely populated urban locations using existing facilities, converting an existing facility, or building a dedicated space. Being closer to the customer and using appropriate robotics and automation solutions to lower the cost of picking retailers can reduce delivery time and costs. As more and more retailers use this strategy, they require many small facilities.

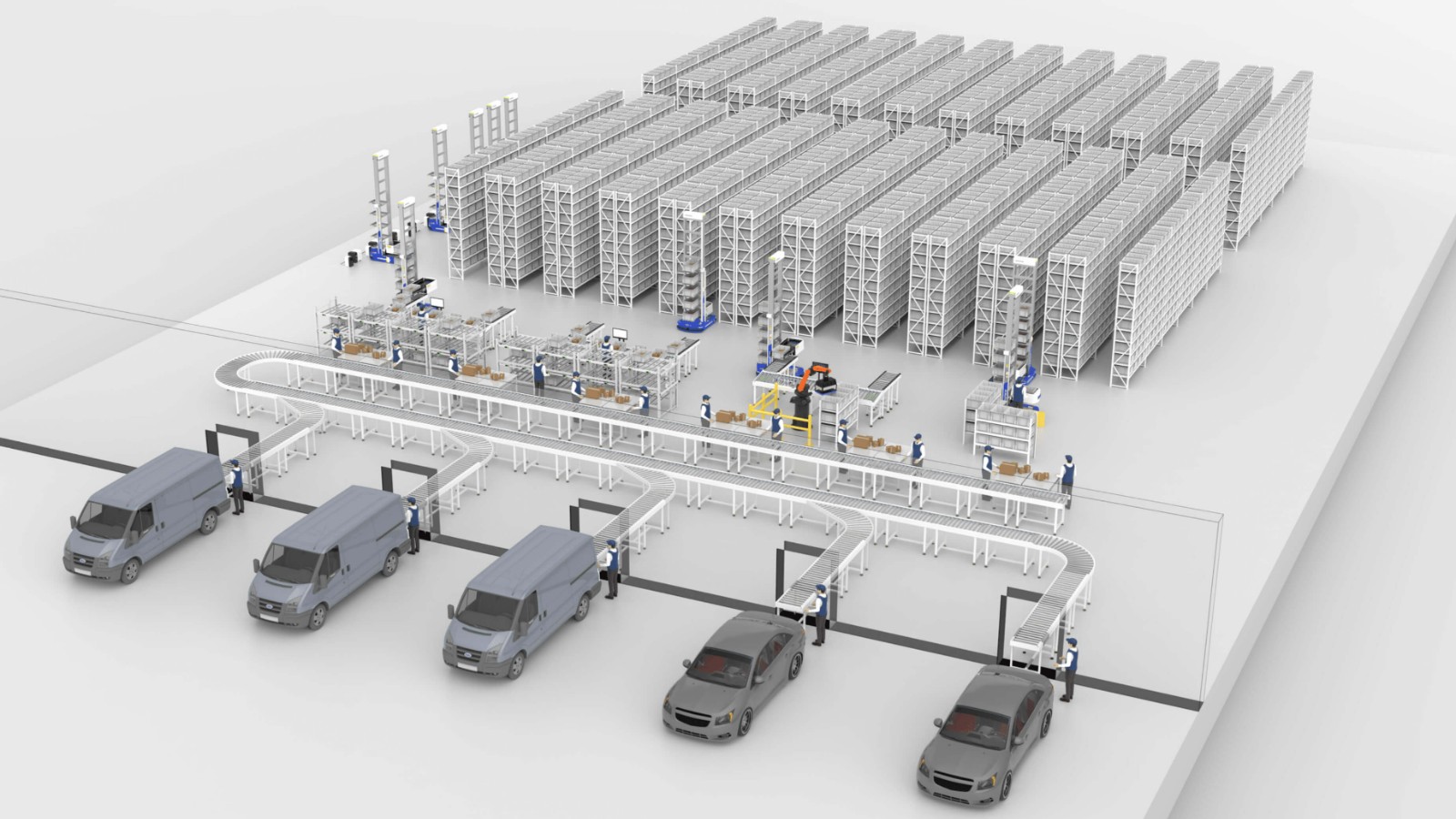

The inclusion of cutting-edge robotics and automation technology plays an important role in the success and proliferation of micro-fulfillment centers. By moving fulfillment closer to the consumer and using robotics and automation solutions such as HAIPICK system for MFC, enterprises can maximize space and increase order fulfillment efficiency, realizing an agile and cost-efficient solution.

How is HAIPICK system boosting MFCs in Europe?

HAI ROBOTICS, has deployed its MFC solution in Europe. The solution leverages HAIPICK system benefits to shorten the last mile in the supply chain to enable faster deliveries from supermarkets. The solution only took 1 week to deploy.

Ultra-fast deployment is key for MFCs in Europe. The time it takes to deploy an automation solution in your MFC directly affects your business. You can't stop the operations in your facility for months just to implement a new solution. The faster you get your robots up and running, the quicker you get your ROI. However, due to the physical characteristics of MFCs, some complex solutions are not a suitable fit. For instance, multi-shuttle typically requires a total revamp of your facility, forcing you to replace all existing equipment with a new custom-made installation. Not to mention the challenges to deploying such massive infrastructure in a reduced environment. On the other hand, goods to person robotic systems like HAIPICK system can quickly be deployed and often incorporate existing shelves and bins.

HAI ROBOTICS' first MFC operation features ACR robots picking, transporting, and delivering orders in "pick-up" stores in the Netherlands. The format merges online ordering and a pick-up shop. As soon as the customer places an order, robots immediately get to work to pick & sort orders in the distribution center (DC). The DC prepares the orders in totes that are sent to the pick-up shop. Once the order arrives at the pick-up shop, the tote is put on a conveyor belt which guides the tote to the storage area. The order remains on the shelves until the customers come to pick it up. Once the customer arrives at the pick-up counter, orders can be picked up fast and easily by scanning the app's QR code and within 2 min the ACR robots can fulfill your order. Shoppers can watch as their orders are carried to them by the conveyor belt as part of a cashier-less and hassle-free shopping experience.

Our solution at a glance

The MFC solution from HAI ROBOTICS can be customized to meet storage, picking, and consolidation requirements. In the case of groceries, the HAIPICK system solution can include a combination of ambient, fresh, and chilled environments. Below is an example of a HAIPICK system solution for automated fulfillment centers.

Specifications:

* 20,000 SKUs

* 900+ order line/hour

* Area: 1,000 m2

* Robots: 24 A42

* Workstations: 3 conveyor workstations

Significant advantages:

* ROI: Less than 2 years

* Investment: Under $2 Million

Micro-fulfillment centers benefits

The micro fulfillment center solution from HAI ROBOTICS delivers the following benefits:

* Fast ROI

* Faster and efficient fulfillment

* Flexible integrations into existing facilities, or stand-alone facilities

* High level of customization

* High storage density

* Quick to deploy and commission

* Reduced manual labor

* Flexibility to adapt to a wide variety of market segments

* Full lifecycle customer support

Source links:

(1) Ecommerce Statistics: Industry benchmarks & growth

(2) What does ‘micro-fulfilment’ mean for the future of rapid delivery?